On site we have a diverse range of equipment and facilities to ensure we manufacture our bespoke and generally quite unusual products to perfection. The manufacturing process will generally move though our CAD and pattern design studios, before moving onto our high-tech Zund cutter. Once cut the process of welding and tooling can begin.

Pattern and CAD Design

As with many manufacturing processes the team can only be as good as the information they have. That’s why we have invested time and capital into creating the perfect design studio for the job. Once we have an understanding of requirements we’ll start by generating a three dimensional drawing of the item, using mainly our SolidWorks software. If the initial model doesn’t quite match expectations it’s not a problem, we’ll quite literally go back to the drawing board (or PC!).

Once we have a model in place we can press on to the interesting bit, manufacture and the finished product. The product pattern will evolve from the CAD drawings as all the measurements and final dimensions will already be in position. Once we’ve pulled off all the components of the pattern the product is handed over to our high-tech laser Zund cutter. The Zund system incorporates a computer system which will generate the best lay-plan for the components and then will precisely laser cut each component. Neat, efficient and minimal waste giving our machinists the perfect component to work with… every time.

Welders

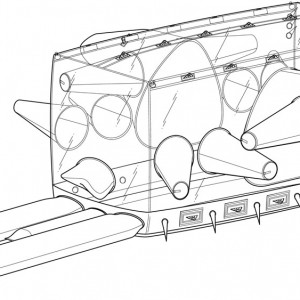

We have multiple welders on site to enhance the capacity of the products we can high-frequency weld. The largest of which is our track welder, ideal for straight welds. All our other welders require specific tooling’s to complete every weld with the perfect finish. Our selection of welders are manufactured by FIAB and Radyne.

Radyne were industry pioneers in Radio Heaters as early as 1946. In modern times known as Inductotherm which covers all heating and welding technologies. The early technology was used during wartime Britain as a method of heating metals without contacting them. Later discovering the cleaner, compact, controllable and more flexible heating process – perfect for plastic. Radyne now manufacture in America and the welder has taken a back foot in our production.

We have multiple FIAB machines and compatible toolings to ensure we can create perfect the perfect weld in any desired shape. The real workhorse of our FIAB machines is the FIAB 900 an all-round high frequency welding machine with up to 2000mm tool length for applications. The 900 operates with a unique pneumatic system, reducing material and tool change over times. We have this machine an others similar to complete a diverse range of tricky welds. For large straight welds we have two large track welders. These are specifically designed to give a straight and tight join over two fabrics or plastics.