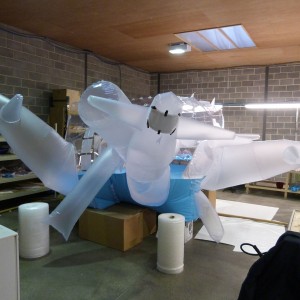

The Bed Isolator is the largest and toughest of MoD/NHS isolation units we manufacture. It requires a number of intricate components mounted onto a vast airtight ‘shell’. It is important to note that the needs of the Bed Isolator are ever changing and we respond to this with regular alterations, required to ensure the equipment is best suited for the medical profession.

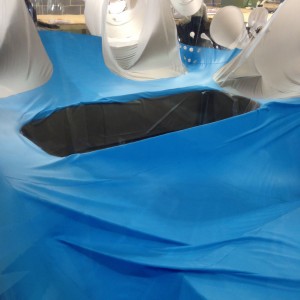

The aim is for the Bed Isolator to allow for the best hospital care for the patient whilst protecting medical staff from all contamination risks. All Flexiplastics Bed Isolators are subject to rigorous quality testing and will undergo a pressure test to ensure the isolator is gas tight. When in use the unit is hung and is operated under a negative pressure.

The isolator includes four medical ‘half suits’ which allow the operative to enter the unit safely. These are fitted with specialist viewing areas and an internal area to house a stethoscope.

Supporting the half suits there is a network of welded components necessary for administering treatment. These include:

- Glove Sleeves

- Bespoke x-ray chamber

- Petite ‘cones’ – to allow drips or wires to enter safely

- Phone pouch – for mobile phone use if desired

- Long tubes – which hold waste or medical debris – which can later be cut away from the isolator and resealed

- An area where a ‘bed’ can be raised within the unit